OEM Aluminum Die Cast Auto Parts Vacuum Die Casting for Car Parts

Overview Package Size 120.00cm * 80.00cm * 80.00cm Package Gross Weight 310.000kg OEM Aluminum Die Cast Auto Parts Vacuu;

Overview

Product DescriptionPRODUCT INTRODUCTION

The advantages of aluminum alloy auto parts over steel parts outweigh its disadvantages. More and more manufacturers are experimenting with relatively expensive aluminum die-castings because it is lighter than steel. It makes the car leaner and faster. It also helps achieve fuel efficiency standards - since lighter vehicle means less fuel used. So the expensive material makes up for the cheaper fuel consumption of the car in the long run. There are several luxury models that are made with aluminum car frames. This is in fact a few times more expensive than steel cars but the user will be ensured that it would help save energy. Environmental advocates will love it more because it is almost a hundred percent recyclable - another standard that aluminum helps achieve.

ADVANTAGES OF OUR CASTING PROCESS

1. Close ToleranceOur castings are made in metal molds so dimensional variation from piece to piece is negligible and close tolerance is consistently held. Our ability to achieve the highest accuracy and precision has allowed us to successfully cast many parts that have been used without machining, resulting in remarkable savings for our customers.2. High QualityProcess control and upfront engineering are the keys to guaranteeing high-quality castings. This is probably why Gupta Permold exceeds the industry standards for internal scrap and failure rates. In summary, Gupta Permold strives for Zero-Defects by continuously monitoring all processing and investing painstaking effort into tooling development and designs.3. Complex Shapes complexOur molds are machined out of blocks of high-grade steel. As evidenced by the casting above, complex shapes with thin walls can be cast using ingenious coring techniques so no machining is needed. Undercuts are routinely cast with the use of sand cores, and sometimes, even without. Fully machined cavities, intricate coring techniques, and state-of-the-art molding make complex aluminum parts a routine task for Gupta Permold.

Detailed Photos Powder coating

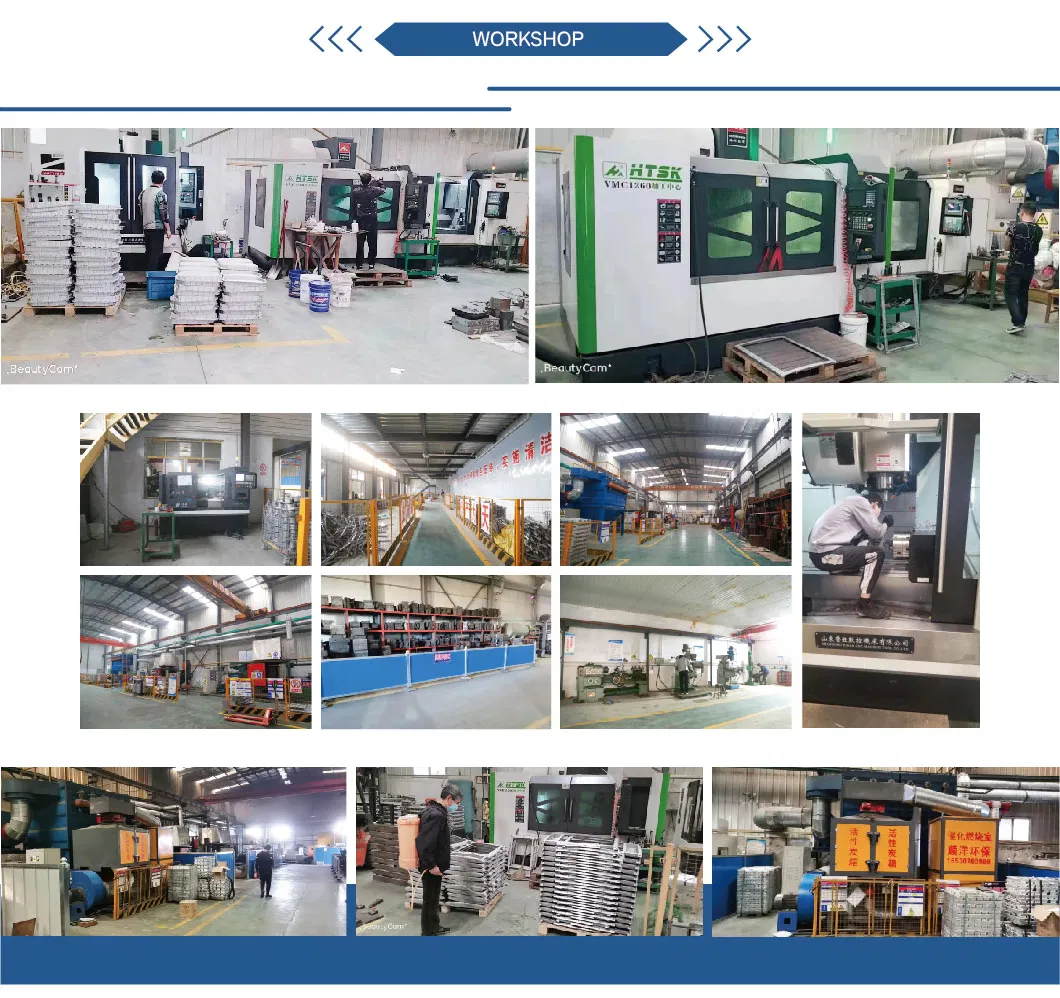

We are a factory. We provide you one-stop service, from mold design to finish part.

Q2:Where is your factory?

Our factory located on Cangzhou which is a beautiful city which is very near Beijing and Tianjin city. You can fly to Shanghai Beijing Capital International Airport (BCIA) or Tianjin Binhai International Airport (TSN), we will pick you up at the airport.

Q3:How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing (IGS or STP format)

Second, Our engineers will check the drawing carefully and then provide you a better price.

Third, If you accept, then order confirmed.

Q4: How does the payment process work ?

Payment terms are flexible for us in accordance with specific conditions . Generally we advise 30% TT advance , Balance be paid before shipment.

If you have another question, please feel free to contact us .

Q5: What will you do after sales ?When our aluminum parts apply to your products ,we will follow up and await your feedback . Any questions related to our metal parts , our experienced engineers are ready to help.

Basic Info.

| Model NO. | Aluminum Alloy Auto Parts |

| Machining | CNC Machining |

| Material | Aluminum |

| Surface Preparation | Powder Coating / Electrophoretic Paint |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 2 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Usage | Car |

| OEM | Yes |

| Key | Aluminum Die Casting |

| Designs | as Per The Customer′s Drawings |

| Technology | Cast Aluminum |

| Thickness | OEM Size |

| Colour | OEM Color |

| Transport Package | Wooden Box |

| Specification | Customized |

| Trademark | R&H |

| Origin | Cangzhou |

| Production Capacity | 500000PCS/Year |

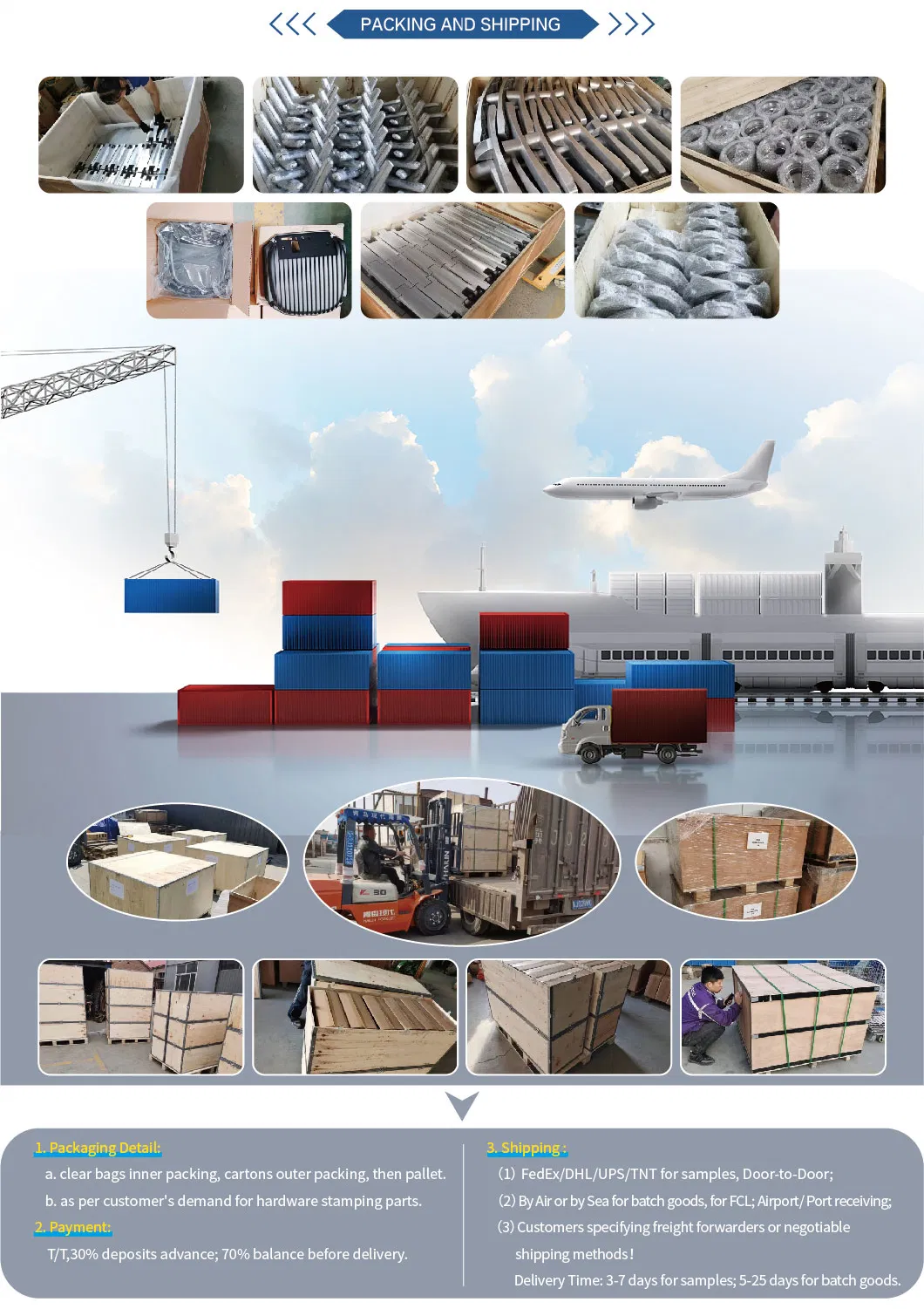

Packaging & Delivery

Package Size 120.00cm * 80.00cm * 80.00cm Package Gross Weight 310.000kgProduct Description

OEM Aluminum Die Cast Auto Parts Vacuum Die Casting for car parts Product Parameters| DIAMETER | Customized |

| THICKNESS | OEM size |

| SURFACE TREATMENT | Powder coating / Electrophoretic paint |

| COLOUR | OEM color |

| MATERIAL | Aluminum |

| TECHNOLOGY | Aluminum Die Casting |

| APPLICATION | Cars / Trucks / Auto parts |

The advantages of aluminum alloy auto parts over steel parts outweigh its disadvantages. More and more manufacturers are experimenting with relatively expensive aluminum die-castings because it is lighter than steel. It makes the car leaner and faster. It also helps achieve fuel efficiency standards - since lighter vehicle means less fuel used. So the expensive material makes up for the cheaper fuel consumption of the car in the long run. There are several luxury models that are made with aluminum car frames. This is in fact a few times more expensive than steel cars but the user will be ensured that it would help save energy. Environmental advocates will love it more because it is almost a hundred percent recyclable - another standard that aluminum helps achieve.

ADVANTAGES OF OUR CASTING PROCESS

1. Close ToleranceOur castings are made in metal molds so dimensional variation from piece to piece is negligible and close tolerance is consistently held. Our ability to achieve the highest accuracy and precision has allowed us to successfully cast many parts that have been used without machining, resulting in remarkable savings for our customers.2. High QualityProcess control and upfront engineering are the keys to guaranteeing high-quality castings. This is probably why Gupta Permold exceeds the industry standards for internal scrap and failure rates. In summary, Gupta Permold strives for Zero-Defects by continuously monitoring all processing and investing painstaking effort into tooling development and designs.3. Complex Shapes complexOur molds are machined out of blocks of high-grade steel. As evidenced by the casting above, complex shapes with thin walls can be cast using ingenious coring techniques so no machining is needed. Undercuts are routinely cast with the use of sand cores, and sometimes, even without. Fully machined cavities, intricate coring techniques, and state-of-the-art molding make complex aluminum parts a routine task for Gupta Permold.

Detailed Photos Powder coating

Out-gassingWhen powder coating is applied to our products, we are able to minimize the out gassing which generally occurs and is known to lead to unsightly pinholes. This is mainly due to Gupta's advanced electrical melting techniques, metal cleanliness practice, and superior aluminum grain structure.

We are a factory. We provide you one-stop service, from mold design to finish part.

Q2:Where is your factory?

Our factory located on Cangzhou which is a beautiful city which is very near Beijing and Tianjin city. You can fly to Shanghai Beijing Capital International Airport (BCIA) or Tianjin Binhai International Airport (TSN), we will pick you up at the airport.

Q3:How to order?

First, Customer could send us your sample or drawing, such as 2D and 3D drawing (IGS or STP format)

Second, Our engineers will check the drawing carefully and then provide you a better price.

Third, If you accept, then order confirmed.

Q4: How does the payment process work ?

Payment terms are flexible for us in accordance with specific conditions . Generally we advise 30% TT advance , Balance be paid before shipment.

If you have another question, please feel free to contact us .

Q5: What will you do after sales ?When our aluminum parts apply to your products ,we will follow up and await your feedback . Any questions related to our metal parts , our experienced engineers are ready to help.

You may also like

Send inquiry

Send now