Nickel Based Alloy RC Jet Engine Nozzle Guide Vane Vacuum Casting

Basic Info.

| Model NO. | Boyuan Casting |

| Surface Roughness | Ra3.2 |

| Machining Tolerance | +/-0.01mm |

| Standard | ASME |

| Certification | CE, ISO 9001:2015 |

| Package | Carton Box, Plywood Cases |

| Service | OEM and Customized |

| Size | as Per Customer′s Requirements |

| Usage | Turbojet Engine, Engine Turbocharger |

| Sample | 1 or 2 Pieces |

| Technics | Lost Wax Casting |

| Machining Service | Yes |

| Surface Treatment | Sand Blasting and Polishing |

| Raw Material | Inconel 713/718 |

| Item | Nozzle Ring |

| Transport Package | Plywood Case |

| Specification | OEM and Customized |

| Trademark | BOYUAN |

| Origin | Weifang |

| HS Code | 8412901090 |

| Production Capacity | 50000PCS/Year |

Product Description

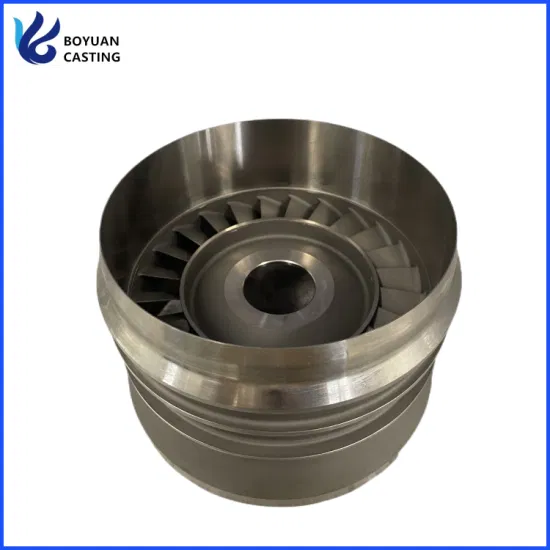

Nickel Based Alloy RC Jet Engine Nozzle Guide Vane Vacuum Casting

Superalloy nozzle guide vane used for Turbojet Engine, Locomotive and Marine turbocharger, it is finished by integral casting. And casting method is lost wax investment & vacuum casting, casting surface smoothness can meet Ra3.2μm, production process is Silica sol process.The blade thickness can be 0.5mm.The material of nozzle guide vane can be Inconel738LC, Inconel713c, Inconel618... Please see the material chemical composition of IN718 for reference:

| Element | C | Cr | Co | Mo | Ni | Fe | Mn | Si | S | Cu |

| Content | ≤0.08 | 17.0-21.0 | ≤1.0 | 2.8-3.3 | 50-55 | BAL | ≤0.35 | ≤0.35 | ≤0.015 | ≤0.30 |

| Element | Al | Ti | ||||||||

| Content | 0.2-0.8 | 0.65-1.15 |

Detailed Photo

About casting production equipments we have: * Aluminum low pressure casting furnace * Vacuum casting furnace * Injection wax machine * Shell drying line * Constant temperature and humidity room * Plaster shell chamber * Sandblasting machine * Heat treatment furnace

About machining production equipments we have: * DMG five axis machining center * Three axis machining center * Doosan CNC center Lathe * General CNC Lathe * Dynamic balancing machine * Overspeed testing machine * Radial Drilling machine

2. Iron base alloy (K213/HU/HW…)

3. Cobalt base alloy

4. Tungsten base alloy

5. Stainless steel (201,202,301,303,304,304H,304L,305,309S,316,316Ti,317,317L,316N ect,…)

6. Aluminum alloy (C355/ZL102/A380A…)

Capacity Instruction:

1.Sample precision field surveying and mapping, Complete custom processing.

2.According to the graphic drawing,realize 3d modeling, customized production.

3.The company built workshop 20000 m2, we have several professional engineer and inspector, production lines working at the same time, promise the products delivery on time

4.When production, we finish different testing include: Raw material inspection, first products inspection, process inspection and final inspection, we make sure our customer receive qualified products.

| Warranty | N/A |

| Customized support | OEM, ODM |

| Place of Origin | China |

| Shandong | |

| Model Number | Customized |

| Brand Name | OEM/ODM |

| Product name | Nozzle Ring |

| Material | Inconel Alloy |

| Size | Customer's Drawing Required |

| Feature | High Precision |

| Service | OEM\ODM |

| Port Size | Standard/Customized |

| Packing | Carton/Wooden Cases |

| Surface Treatment | Coating |

Our Advantages:

1>Fully automatic the free cylinder pressure wax machine

2>Water blasting machine for surface treatment of high standards

3>Constant temperature and humidity system shell pipeline

4>Efficient vacuum melting and casting furnace

5>Automatic large heat treatment furnace

6>Aluminum alloy low pressure casting machine

7>Hot steam dewaxing autoclave

8>high degree of automation equipment

9>Almost 20 years of manufacture & customer service experience

10>OEM service offer

Quality Control

We have full set of quality control system to guarantee best product quality. Depends on the products, we make different item testing plan, different manufacturing procedure and provide certified lab mechanical testing.

FAQs:1.What materials do you cast and machining?We can cast and machining aluminum alloy parts and high temperature alloy parts.2. How can I get the quotation?Please send us information for quote: drawing, material, weight, quantity and request.3.If we don't have drawing, can you make drawing for me?Yes, we make the drawing of your sample and duplicate the sample.4.When can I get the sample?Sample: 25-30 days after you start to make mold. The accurate time depends on your detailed requirements.5.What is your main order time?Order time: 30-40 days after the payment. The accurate time depends on your detailed requirements.6. What is your payment method?Tooling: 100% TT advanced.Batch order: 50% deposit, balance 50% to be paid before shipment.7. Which kind of file format you can read?PDF, ISGS, DWG, STEP, STP,X-T...Welcome to inquire us if there is anything you are interested!